What Is a 3 PCB High Duty Cycle Electric Welding Machine?

A 3 PCB High Duty Cycle Electric Welding Machine is designed for high-performance industrial use, offering stable operation and enhanced durability. The “3 PCB” structure refers to the use of three separate printed circuit boards that manage power conversion, control systems, and output regulation independently. This design improves heat dissipation and ensures reliable performance even during long welding sessions. With a 3 PCB High Duty Cycle Electric Welding Machine, users can operate for extended periods without overheating, which is crucial for heavy fabrication tasks. The machine's strong arc stability and efficient current control make it suitable for various metals, including mild steel, stainless steel, and low-alloy steel.

Why Are Portable MMA Welders Gaining Popularity?

In recent years, the Portable MMA Welder has become an essential tool for on-site maintenance, construction, and small fabrication work. Its compact structure allows welders to carry it easily, making it ideal for outdoor or remote operations. Despite its small size, the Portable MMA Welder can handle a wide range of electrodes and provides excellent arc control thanks to inverter technology. This makes it useful for repairing pipelines, machinery, and structural components. Many professionals appreciate that a Portable MMA Welder offers both reliability and flexibility—allowing high-quality results without requiring bulky industrial equipment. Its mobility and simple setup process also make it suitable for home workshops and mobile service operations.

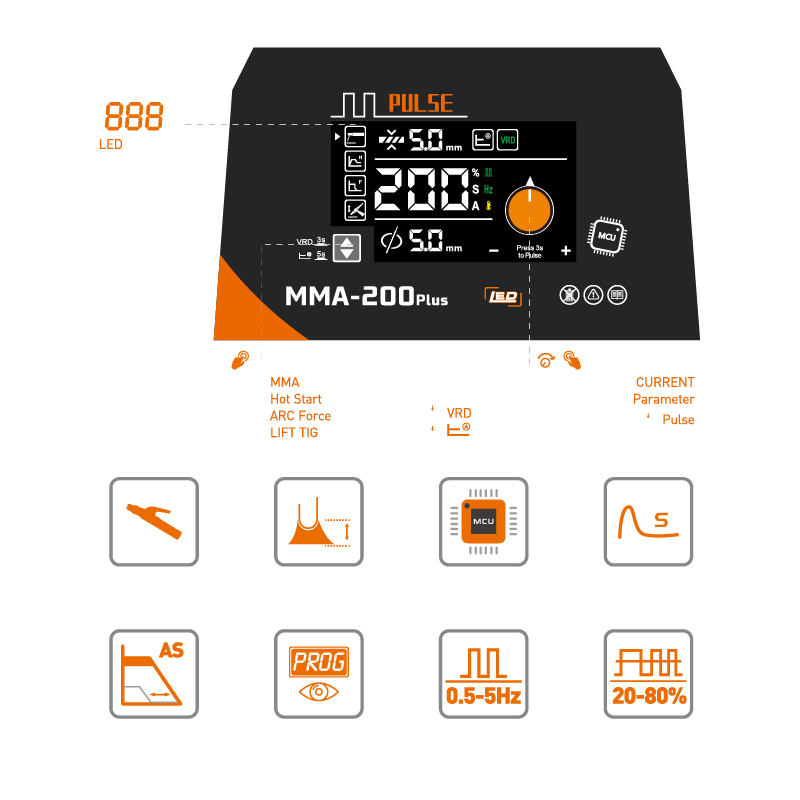

How Does an Inverter IGBT Welder Improve Performance?

The Inverter IGBT Welder utilizes Insulated Gate Bipolar Transistor (IGBT) technology to achieve better efficiency and power regulation. Compared with older transformer-based systems, this machine converts electrical energy more efficiently, resulting in smoother arcs and lower power consumption. The Inverter IGBT Welder also provides fast response to voltage fluctuations, helping to maintain stable output even in challenging power environments. In addition, its lightweight design makes it easy to transport and install, meeting the needs of both industrial users and individual welders. For tasks that require precision and consistent penetration, an Inverter IGBT Welder delivers dependable performance across different materials and thicknesses.

How Do These Welding Machines Complement Each Other?

Each of these machines serves a specific purpose within the welding industry. A 3 PCB High Duty Cycle Electric Welding Machine is built for long-duration, high-intensity operations, making it ideal for factory production lines. A Portable MMA Welder, on the other hand, is best suited for quick repairs and mobile applications, where ease of transport is crucial. The Inverter IGBT Welder combines both efficiency and versatility, bridging the gap between heavy-duty and portable systems. Together, these machines reflect the industry's focus on energy efficiency, improved control, and user-friendly designs.

What Trends Are Shaping the Future of Welding Equipment?

The welding industry continues to evolve toward smarter, more efficient technology. Systems like the 3 PCB High Duty Cycle Electric Welding Machine now integrate digital control features that ensure consistent quality during continuous operation. Similarly, the Portable MMA Welder is being refined with better insulation, cooling systems, and ergonomic designs. The Inverter IGBT Welder remains central to this evolution, as it supports both traditional and advanced welding techniques while reducing energy costs.

As manufacturers and fabricators seek greater productivity, the combination of inverter technology, high duty cycles, and portable solutions will define the next generation of welding equipment. By understanding how each type functions and where it performs best, users can make informed choices that improve both efficiency and welding results.