What Is Pulse MMA Inverter Welding and How Does It Work?

Pulse MMA Inverter Welding is an advanced version of the traditional Manual Metal Arc (MMA) welding process, designed to improve arc stability and control. In this method, the welding current alternates between a high “pulse” level and a lower background level, allowing better heat management and smoother metal transfer. Unlike conventional welding systems, Pulse MMA Inverter Welding uses inverter technology to precisely control the waveform, which results in cleaner welds, less spatter, and reduced distortion. The pulsed current also enables better penetration and reduces the risk of burn-through on thin materials. This makes it a valuable process for applications requiring both strength and visual quality.

Why Is the Pulse MMA Inverter Welding 7018 Rod Combination So Effective?

The Pulse MMA Inverter Welding 7018 Rod setup is widely appreciated for its balance of performance and versatility. The 7018 electrode is known for producing strong, low-hydrogen welds with excellent mechanical properties, particularly on carbon steel and low-alloy steel. When used with pulsed current, the rod's arc becomes more stable and easier to control, especially in vertical or overhead positions. The Pulse MMA Inverter Welding 7018 Rod also delivers smoother bead appearance and fewer defects, making it ideal for structural fabrication, heavy machinery repair, and pressure vessel work. In industrial environments where consistent weld quality is essential, this combination provides both reliability and efficiency.

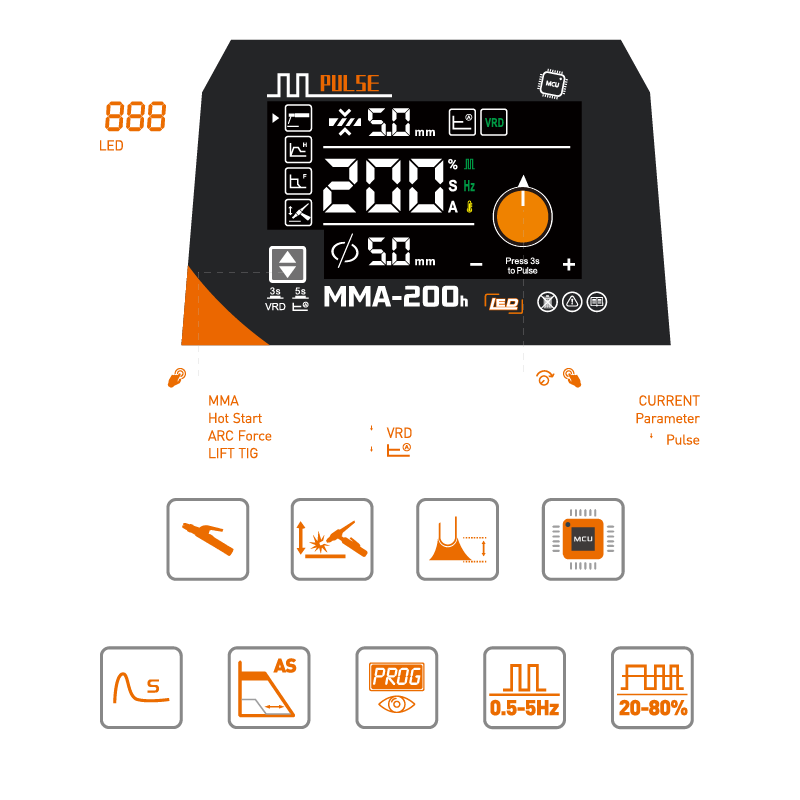

How Does the IGBT Pulse MMA Welder Improve Welding Efficiency?

The IGBT Pulse MMA Welder is built on Insulated Gate Bipolar Transistor (IGBT) technology, which enhances power conversion and reduces energy loss. Compared to older transformer-based machines, this equipment offers faster response times and more stable output. The IGBT Pulse MMA Welder ensures precise control of pulse frequency and amplitude, allowing welders to adapt quickly to different materials and thicknesses. Moreover, it is lightweight and compact, making it easier to transport and operate in various work environments. Many professionals appreciate how the IGBT Pulse MMA Welder delivers consistent arc performance, even under fluctuating power conditions. This results in improved weld penetration, reduced electrode wear, and better overall efficiency.

What Are the Industrial Applications of These Welding Systems?

Pulse-controlled welding systems are increasingly used in industries where precision and durability are critical. The Pulse MMA Inverter Welding 7018 Rod is commonly found in shipbuilding, construction, and equipment manufacturing. Meanwhile, Pulse MMA Inverter Welding in general is suitable for joining mild steel, stainless steel, and hardfacing applications. The IGBT Pulse MMA Welder supports a wide range of electrodes and provides adaptability for both field and workshop use. Together, these technologies enable manufacturers to achieve high-quality joints with lower heat input and less rework.

How Do These Technologies Shape the Future of Manual Arc Welding?

The integration of pulsed current control and inverter-based circuitry marks a significant improvement in traditional welding techniques. As production demands evolve, Pulse MMA Inverter Welding and related technologies like the IGBT Pulse MMA Welder offer the flexibility to meet higher standards of efficiency and accuracy. When paired with consumables such as the Pulse MMA Inverter Welding 7018 Rod, welders can achieve durable results with reduced energy consumption and better handling comfort.

By combining smart power electronics with refined arc control, modern pulse welding systems continue to enhance quality and productivity across industries. Their role in construction, manufacturing, and maintenance proves that innovation in welding equipment is essential for meeting today's industrial challenges.