What Is a Thick Plate Plasma Cutting Machine and How Does It Work?

A Thick Plate Plasma Cutting Machine is designed to cut through dense metal plates using a high-velocity jet of ionized gas. The machine generates extreme temperatures that melt the metal while the plasma jet blows away the molten material, creating a precise cut. This process allows operators to cut thick steel plates efficiently and with minimal heat distortion. The Thick Plate Plasma Cutting Machine is widely used in workshops, fabrication plants, and heavy industries, offering improved speed and accuracy compared to traditional cutting methods like oxy-fuel torches or mechanical saws.

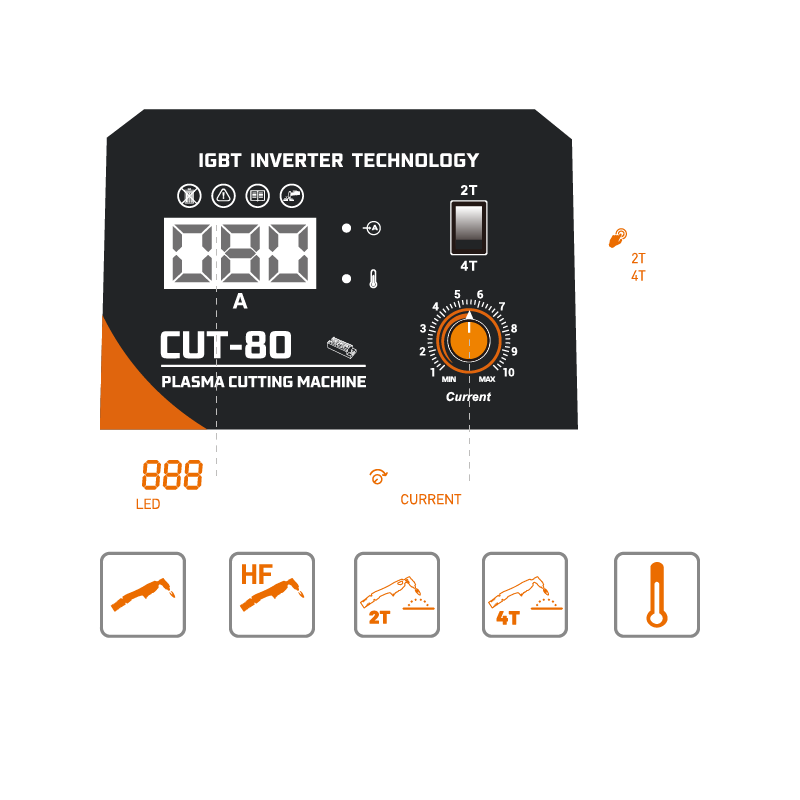

How Does a Thick Plate Plasma Cutting Machine 100a Differ from Standard Models?

The Thick Plate Plasma Cutting Machine 100a is equipped with a 100-ampere power source, which provides stronger cutting capacity for thicker materials. With this higher current, the Thick Plate Plasma Cutting Machine 100a can handle metal plates that are difficult to cut with lower-powered systems, while maintaining smooth edges and consistent cutting quality. This makes it suitable for structural steel, shipbuilding, and heavy machinery fabrication. The 100a rating ensures that operators can work on demanding projects without frequent interruptions or slow cutting speeds.

What Are the Features of an Industrial Plasma Cutting Machine?

An Industrial Plasma Cutting Machine is built for heavy-duty and continuous operation in manufacturing and fabrication environments. Compared to smaller units, the Industrial Plasma Cutting Machine provides stable arcs, precise cuts, and high cutting speed for large-scale metal plates. These machines often come with automated features, such as CNC controls, to improve efficiency and reduce operator fatigue. The Industrial Plasma Cutting Machine is also capable of handling various metals, including stainless steel, aluminum, and carbon steel, making it versatile for diverse industrial applications.

How Are Thick Plate Plasma Cutting Machines Used Across Industries?

The Thick Plate Plasma Cutting Machine series, including the Thick Plate Plasma Cutting Machine 100a and Industrial Plasma Cutting Machine, is widely adopted in industries that require precision cutting of heavy materials. In shipbuilding, these machines cut large steel sheets accurately, ensuring tight tolerances for assembly. In the construction sector, they are used for fabricating beams, frames, and other structural components. Industrial fabrication plants benefit from the Industrial Plasma Cutting Machine for high-volume production, where speed and reliability are crucial. By selecting the appropriate machine for the material thickness and workload, operators can maintain consistent quality and operational efficiency.

Why Is Choosing the Right Plasma Cutting Machine Important?

Selecting the correct machine, whether a Thick Plate Plasma Cutting Machine, a Thick Plate Plasma Cutting Machine 100a, or an Industrial Plasma Cutting Machine, directly affects productivity, cut quality, and safety. The Thick Plate Plasma Cutting Machine is suitable for general workshop applications, while the 100a model offers higher power for demanding thick-plate tasks. An Industrial Plasma Cutting Machine provides the durability and stability needed for continuous, large-scale operations. Understanding the specific capabilities of each machine allows companies to match equipment to their production needs, reduce material waste, and achieve precise, consistent results.

By integrating high-powered plasma cutting technology with robust industrial designs, these machines enable efficient, accurate, and safe processing of metal plates in both small workshops and large-scale manufacturing environments.